Send us an email info@evaautoindustries.com

Send us an email info@evaautoindustries.com

Manufacturing

To achieve perfect finish, the parts are assembled and painted on mechanized lines. These salient manufacturing capabilities in conjunction with a vision to excel has earned EVA Automotive Industries Pvt. Ltd. accolades and award from states and national and international bodies.

Our manufacturing unit in Mundka Industrial Area (Delhi) backed by great expertise is fully equipped to meet all challenges. EVA Industries Pvt. Ltd. manufactures high quality automotive components in its state-of-the-art manufacturing unit, which is well equipped with modern machinery and skilled personnel to meet international standards. All the products are manufactured using high quality raw material.

EVA Automotive Industries Pvt. Ltd. is proud to have all manufacturing equipment under one roof: -

Quality

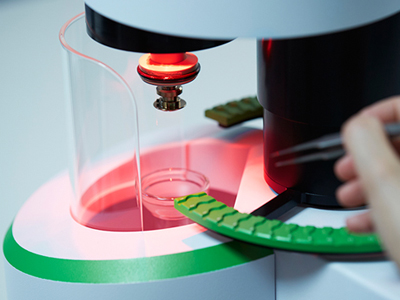

Ours is a tool room equipped with modern-day machinery. It is utilized for revitalizing products and innovate them for reducing the manual efforts or procedures. This becomes an apprentice for the business by providing it an upper hand over competitors in the industry.

Product Development Quality

The entire product development quality check is performed in a grapevine manner. Our bureau stringently conducts analysis and file reports after assessing the product quality as per the pre-set industry parameters. This helps us in gaining an appropriate idea of the client’s requirements.

R & D

We have own tool room where we work Directed towards the innovation, introduction, and improvement of products and processes. It helps a business to have a competitive edge over its competitors for this process we use some machines for the same.

List of All Products: -